Automotive Industry

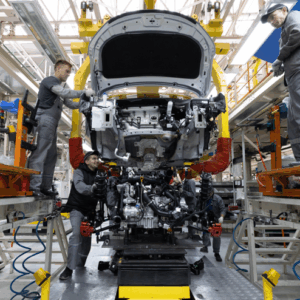

Facilities expansion of vehicle paint system

Installing production lines for new car models and integrated with printing sectors, paint and final assembly.

This industry was to install a distribution system between medium voltage substations integrated into EPMS to suit the plant demand control. For transportation between the sectors of the factory, has been mounted 4300 meters of overhead conveyors and 800 meters floor carrier having directional sensors to optimize the routes between production areas. The stamping area was installed 12 presses 32 tons integrated with 24 axias robots in communication with the production control room. This room is installed 6 servers with CAD / CAM that has functions to model the pieces which are Full Print in the press line. In the spray area of the cars were installed 1800 meters of overhead conveyors for bodyshell transportation to the sector with the 6 cabins of paintings and 8 axial robots in each production line. To increase production routes were built for automated guided vehicle systems (AGVs) between the paint industry and the final assembly sector.

They were installed three substations with two transformers of 4,500 KVA that distribute energy through 7,500 meters busway for the working cells in the areas of production.

To control and production safety have been installed 42 cameras connected to servers inside the control room that was built on the second floor, monitoring all areas. The commissioning was performed in stages which were measured through the process variables reported in design. In the production sector with robots in work cells (Robot Workcells) time parameters were analyzed, welding finishing (spot welding and arc welding) Welding Robot applied by the different types of steel sheets. In the painting line was checked productivity and quality of Robot Spray Painters in paint booths. The power system and central utilities have been tested with the automation implemented for remote management by the customer’s Corporate Headquarters. We conduct tests with sequencing at startup and general shutdown of the plant to ensure that does not create unsafe conditions and performance of systems redundancy for critical mission areas of the plant. We follow the ramp up of production together with clients from every sector.

inside the control room that was built on the second floor, monitoring all areas. The commissioning was performed in stages which were measured through the process variables reported in design. In the production sector with robots in work cells (Robot Workcells) time parameters were analyzed, welding finishing (spot welding and arc welding) Welding Robot applied by the different types of steel sheets. In the painting line was checked productivity and quality of Robot Spray Painters in paint booths. The power system and central utilities have been tested with the automation implemented for remote management by the customer’s Corporate Headquarters. We conduct tests with sequencing at startup and general shutdown of the plant to ensure that does not create unsafe conditions and performance of systems redundancy for critical mission areas of the plant. We follow the ramp up of production together with clients from every sector.

Technical Summary

Design, planning and electromechanical installation of 3500 meters of overhead conveyors to 10 Tons and 2,200 meters floor conveyors involving metal structure, 435 tons of equipment platforms, control panels and power distribution, 8600 meters of pipe compressed air unit demineralization by reverse osmosis with 3 tanks of 186 cubic meters of water tanks 4 for mounting the process of cathodic dip painting (KTL process), heat exchangers, control valves, instrumentation for process control, automation systems with robots axial, control room with 3 servers and 5 workstations, 2300 meters LAN Category 6, switch and router systems to process biometric, 30 meters of tunnel lighting for quality control monitored with CCTV system, combat system fire, commissioning and tryout.

Design, planning and electromechanical installation of 3500 meters of overhead conveyors to 10 Tons and 2,200 meters floor conveyors involving metal structure, 435 tons of equipment platforms, control panels and power distribution, 8600 meters of pipe compressed air unit demineralization by reverse osmosis with 3 tanks of 186 cubic meters of water tanks 4 for mounting the process of cathodic dip painting (KTL process), heat exchangers, control valves, instrumentation for process control, automation systems with robots axial, control room with 3 servers and 5 workstations, 2300 meters LAN Category 6, switch and router systems to process biometric, 30 meters of tunnel lighting for quality control monitored with CCTV system, combat system fire, commissioning and tryout.