Automation

Design, installation and commissioning of automation system

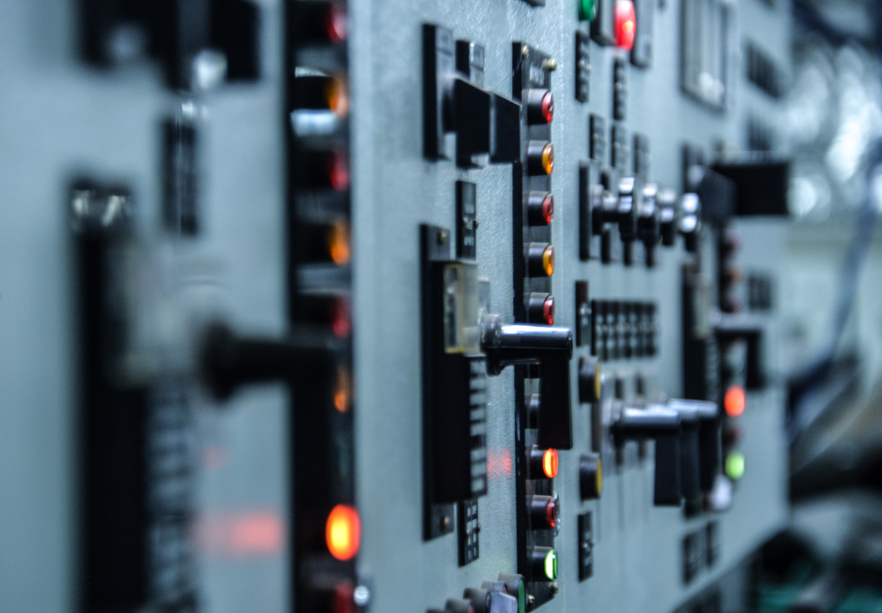

Installation of a system for process control integrated with the power distribution areas, utilities and cogeneration. The main control room was expanded with new network equipment connected to 8 dedicated servers. The system was installed with new single-mode optical fiber connected with IT rooms in the areas involved and connected with the panels in substations, generators and control panels on the production line.

Automation room were installed racks dedicated instrumentation and IEC 61850 Network with infrastructure VLAN within the corporate network.

Technical Summary

Expansion of production Superphosphates and Fluoride

Design and reform of the gas washing system in the area of Superphosphates and fluoride, with DCS-Digital Control Systems installation for process control, electrical infrastructure with 57000 meters of medium voltage cables, 2345 meters of pipe 26 inches for gas, 186 tons of pipe rack, 4877 I/O instrumentation for process control, four control rooms and 43 medium voltage switchgear, 579 tons of steel structure, relocation of four transformers 88 kV / 13.8 kV, 25 MVA.

Installations for the stamping sector

Design and electromechanical assembly expansion of production process with 410 axial robots, 3890 meters for pipe hydraulic system, 8810 meters pipe compressed air, applications for motion and control devices, 8 servers connected by TCP / IP protocol for process control, platforms panels for maintenance, overhead cranes for parts distribution and sensing systems for remote control and management (CAD / CAM) in intranet, substations of 20 MVA – 138 kV generator with power 2500 kVA – 13.8 kV, 12300 meters busway 5000 amperes, HVAC system with 1200 TR, commissioning and tryout.