Engineering

Engineering applied in the construction of industries, commercial buildings, energy, automation, power systems and robotics

Industrial process automation and commissioning of facilities

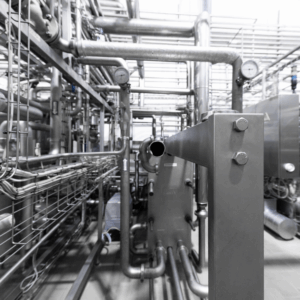

Design, planning and electromechanical assembly of industrial unit with cooling system through Ethylene Glycol involving installation of 03 Polypropylene tanks with 150000 liters each, 102 ultrasonic sensors for level control, 32000 meters of cables for control and process automation, Automation for management of fluid pumping system, panels for electrical power equipment, 13000 meters infrastructure for installation of the system, maneuver and control instruments involving solenoid valves, flow switches, heat exchangers, digital gauges, pipe and mechanical valves of various dimensions, manuals and training for system operation.

Design, planning and electromechanical assembly of industrial unit with cooling system through Ethylene Glycol involving installation of 03 Polypropylene tanks with 150000 liters each, 102 ultrasonic sensors for level control, 32000 meters of cables for control and process automation, Automation for management of fluid pumping system, panels for electrical power equipment, 13000 meters infrastructure for installation of the system, maneuver and control instruments involving solenoid valves, flow switches, heat exchangers, digital gauges, pipe and mechanical valves of various dimensions, manuals and training for system operation.

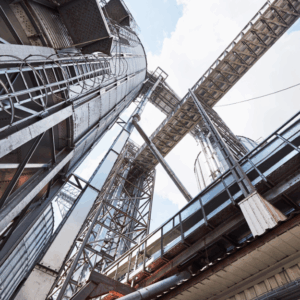

Reform Pellet Plant and automation of the electrical system in medium voltage

Design and Reform of pelletizing silos and mobile grate furnace, 1800 meters of piping for utilities (gas / industrial water), 88 tons of metal structure for pipe rack and walkway, installation of 35 cubicles medium voltage 13.8 kV, 480 I / O for process automation system, lighting, protection system Lightning, expansion control rooms with supervisory and 32 dedicated servers to process control.

Assembly and automation equipment for sector Stamping

Design, planning and electromechanical assembly plant 24 presses with 1,200 tons of press force each, 460 meters of conveyor belt for bodywork with 12 ton capacity, 300 laser sensors and 88 cameras, construction of 132 meters gallery under the bodywork production line for mounting 18 destacking stations for plates with drive by compressed air, 2300 meters of compressed air pipes for 12 bar, installation of accelerometers to control the vibration of equipment, guardrails, 216 tons of platforms for maintenance of equipment, lighting, automated lubrication systems with oil tank and dual filters, assembly equipment, control room with 6 servers and 8 workstations for sequencing, scheduling and balancing of lines production, 8200 meters of optical fiber single-mode / multimode, switches and routers, 03 compact substations SF6 gas -13,8kV – 12MVA, 68 robotic production cells for welding in parts – flexible manufacturing, 854 meters of Busway to 5,000 amps, 2 lines presses 4 tons to tryout, transfer unit for parts equipped with 5 axial robot, 1500 meters of overhead conveyors to 10 tons and 1200 meters of floor conveyors.

Design, planning and electromechanical assembly plant 24 presses with 1,200 tons of press force each, 460 meters of conveyor belt for bodywork with 12 ton capacity, 300 laser sensors and 88 cameras, construction of 132 meters gallery under the bodywork production line for mounting 18 destacking stations for plates with drive by compressed air, 2300 meters of compressed air pipes for 12 bar, installation of accelerometers to control the vibration of equipment, guardrails, 216 tons of platforms for maintenance of equipment, lighting, automated lubrication systems with oil tank and dual filters, assembly equipment, control room with 6 servers and 8 workstations for sequencing, scheduling and balancing of lines production, 8200 meters of optical fiber single-mode / multimode, switches and routers, 03 compact substations SF6 gas -13,8kV – 12MVA, 68 robotic production cells for welding in parts – flexible manufacturing, 854 meters of Busway to 5,000 amps, 2 lines presses 4 tons to tryout, transfer unit for parts equipped with 5 axial robot, 1500 meters of overhead conveyors to 10 tons and 1200 meters of floor conveyors.